Microfluidics Precision Meets Performance

NanoSynthes delivers advanced microfluidic solutions for superior nanocarrier production, enhancing reproducibility, scalability, and encapsulation efficiency.

Our Technology

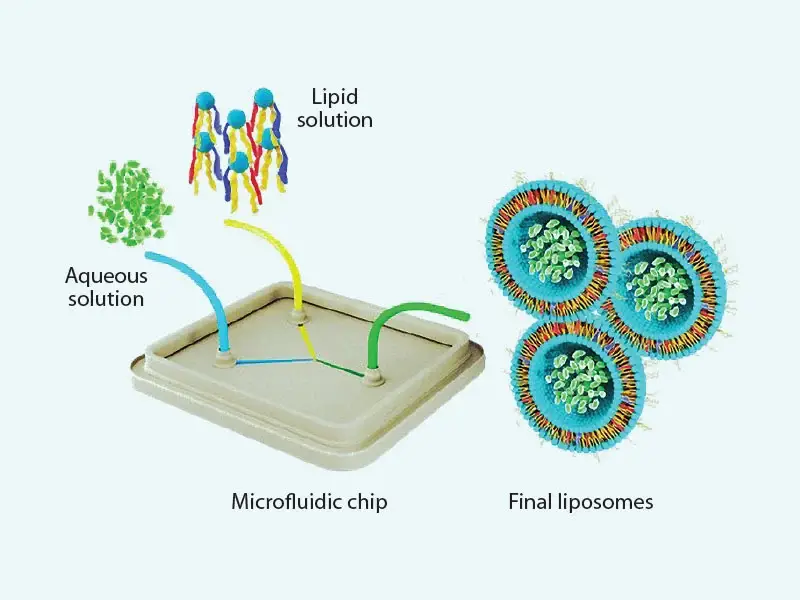

NanoSynthes provides full solutions for the production of various drug nanocarriers at both R&D and Research scale, and Scale-up production for commercialization of biopharma products. Our technology relies on Microfluidics that allows for the production of carriers in a continuous manner that eliminate the need for using size-reduction methods. In this way, size, PDI, and loading of carriers could be easily modulated via controlling the hydrodynamic conditions. NanoSynthes has manufactured equipment that have been successfully characterized for mRNA-Lipid Nanoparticle Covid-19 vaccine.

Microfluidic-based method

- Microfluidics allows for the production of nanocarriers in a continuous manner in one-step

- No need to employ particle size reduction methods

- High reproducibility in production of particles

- Easy modulation of particle size, PDI and drug loading

Advanced Microfluidic Solutions

NanoSynthes delivers complete microfluidic solutions for producing a wide range of drug nanocarriers, from early-stage R&D to large-scale commercial manufacturing.

By precisely controlling hydrodynamic conditions, our technology allows continuous and accurate production of lipid- and polymer-based nanoparticles, ensuring consistent particle size, low polydispersity (PDI), and optimized drug loading efficiency.

🧬 Proven in Critical Applications

NanoSynthes microfluidic systems have demonstrated exceptional performance, notably in mRNA-Lipid Nanoparticle COVID-19 vaccine production. From initial research to GMP-compliant commercial manufacturing, our technology ensures consistent results, seamless scalability, and regulatory compliance, validated through real-world, high-stakes applications.

Extrusion-based methods

- Multi-step process with high investment cost

- Needs particle size reduction methods

- Low reproducibility in production of particles

- Requires highly-trained operators

- Low-throughput and high cost of production

- Low controllability over size optimization

Microfluidic-based method

- Microfluidics allows for the production of nanocarriers in a continuous manner in one-step

- No need to employ particle size reduction methods

- High reproducibility in production of particles

- Easy modulation of particle size, PDI and drug loading

Why NanoSynthes Microfluidics?

| NanoSynthes Microfluidic Method Advantages | Traditional Extrusion-based Methods |

|---|---|

| One-Step Continuous Production | Complex, multi-step processes |

| Efficient and cost-effective, eliminates multiple processing steps. | High investment and operational costs |

| High Reproducibility: Ensures consistent quality, batch after batch. | Requires particle size-reduction methods (extrusion/sonication) |

| Optimized Encapsulation Efficiency: Precisely controls particle properties for maximum drug loading performance. | Low reproducibility and inconsistent batches |

| Scalable from Lab to Industrial Production: Effortlessly transition from small-scale R&D to industrial GMP manufacturing. | Low-throughput with limited scalability |

| Easy Operation & Integration: User-friendly equipment designed for integration into existing laboratory workflows, requiring minimal training. | Needs highly-trained operators |

Take your nanocarrier projects to the next level

Learn more about how NanoSynthes microfluidic solutions can enhance your nanoparticle production process. Connect with our experts for a personalized consultation or technical assistance.